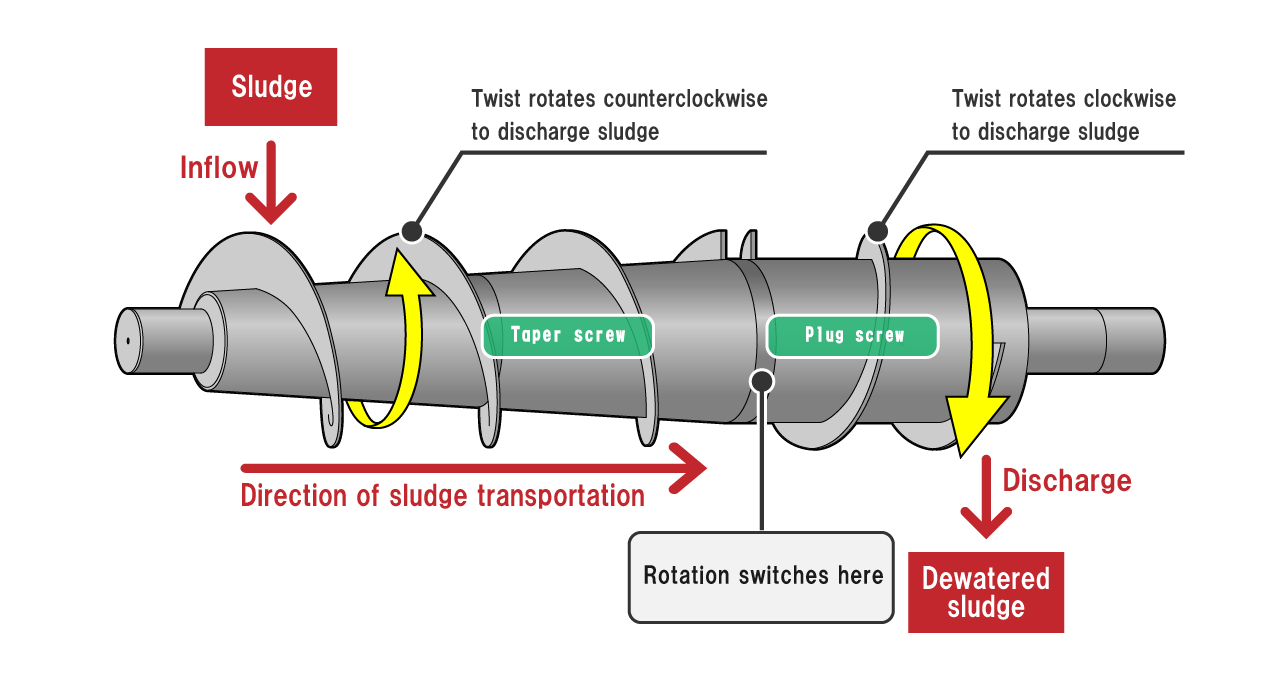

Two stage screw shaft mechanism enables reduced water content

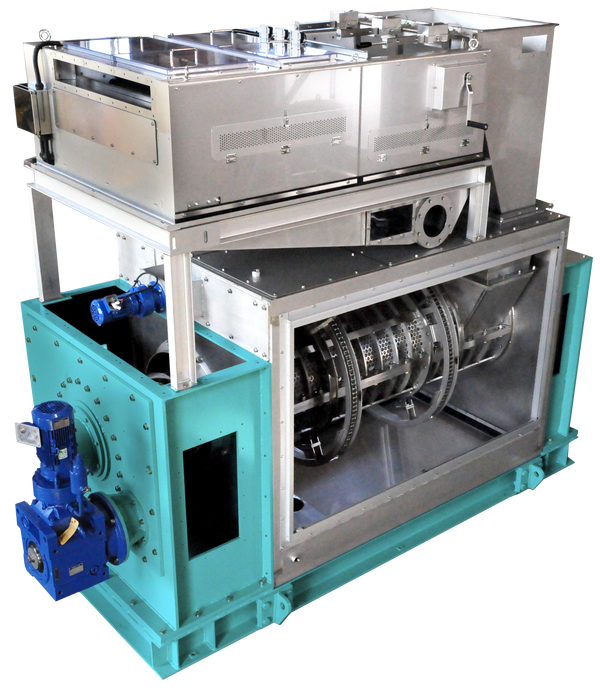

◆Stable Operation

A thorough squeeze of sludge is achieved by fine adjustment to the sludge properties. By eliminating a back pressure plate, leakage and blockage of dehydrated(dewatered) cake hardly occur.

◆Easy Operation

Change of sludge properties can be easily dealt with by adjusting the frequency of two motors. The rear stage shaft (plug screw) can forcibly discharge dehydrated cake.

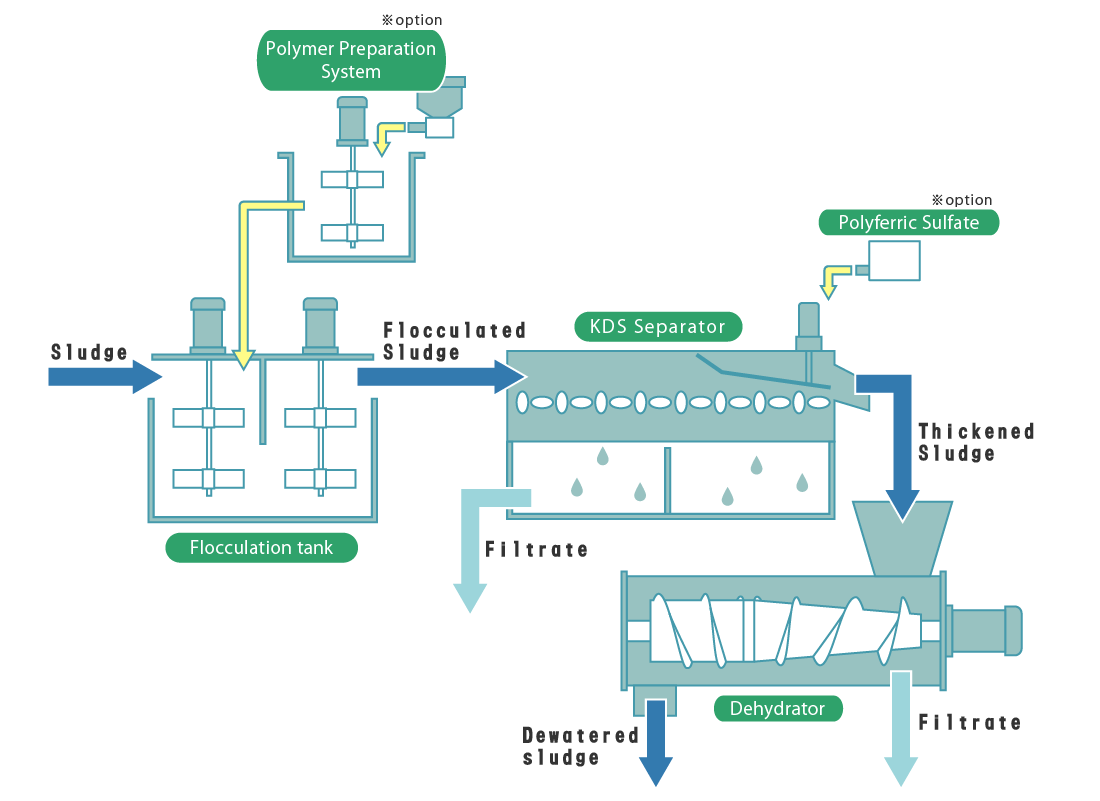

◆High thickening efficiency

By using KDS Separator for pre-thickening, the amount of sludge recovery, the treatment capacity and the dewatering ability are greatly increased. Besides, the amount of backwash water is decreased.

| Model | Treatment Capacity(kg-DS/h) | ||

|---|---|---|---|

| Digested sludge | Mixed raw sludge | OD Excess sludge | |

| DBSP300 | |||

| DBSP400 | |||

| DBSP500 | |||

| DBSP600 | |||

| DBSP700 | |||

| DBSP800 | |||

| Water content for reference | 72% | 59% | 78% |